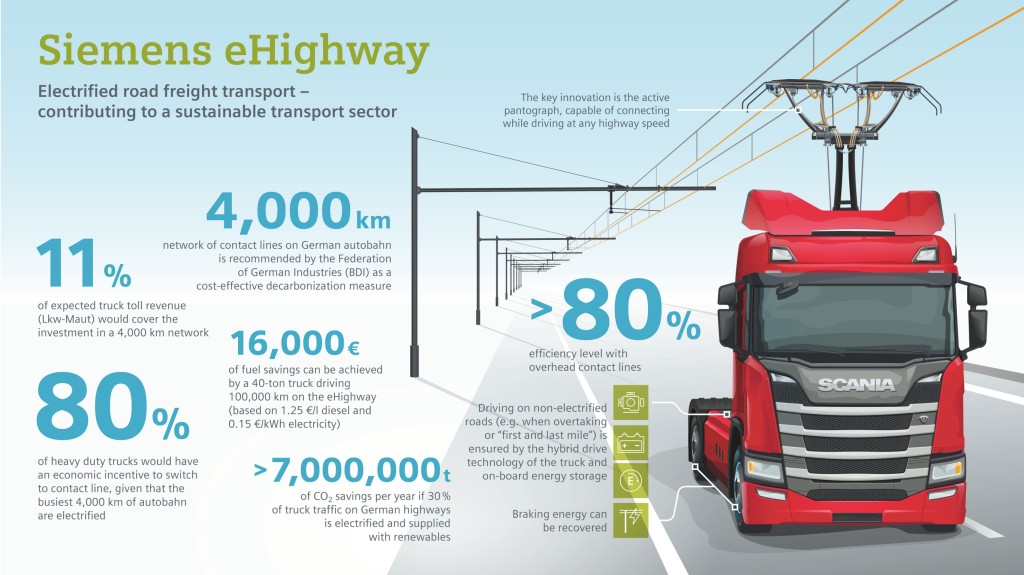

In last 5-7 years, many companies geared up for enabling the e-Highway & Germany came first with an offering which seems to be promising✌️& at the same time, significant reduction😇in pollutant and CO2 emissions can be observed.

First eHighway in Germany

Happy😊to see the maturity level of the e-Highway by Siemens, Scania & German autobahn.

- Installation of an overhead contact line system for electrified freight transport on a ten-kilometer stretch of public autobahn for the customer Hessen Mobil

- Field testing of the eHighway system up to 2022, together with research partner TU Darmstadt and green electricity provider entega

- Scania supplying five overhead line hybrid trucks for this project, with a total of 15 being provided for German field testing

How eHighway works

Energy supply

The energy supply system is based on proven technology from the world of railroad electrification. The two-pole catenary system ensures a reliable energy supply for the eHighway truck. The catenary system leads to a level contact wire that enables stable current transmission, even at high speeds. The overhead contact lines are supplied with energy from substations equipped with:

- Medium voltage switchgear

- Power transformers

- Rectifiers

Controlled inverters (for feedback of the electric energy generated by the vehicles’ regenerative braking).

Pantograph

The active pantograph transmits the energy from the overhead contact lines to the electric motor of the eHighway truck. The pantograph can be easily connected to and disconnected from the contact wire at speeds ranging from 0 to 90 km/h. This is done either automatically or manually at the push of a button. Steering an eHighway truck connected to the overhead contact lines is no different to driving a diesel truck, as the active pantograph compensates for any shifts in position within the lane. The pantograph automatically disconnects in the event of evasive maneuvers or if the indicators are used.

HYBRID Drive

On electrified routes, the electric motors in eHighway trucks are powered via the overhead contact lines and the active pantograph. For remaining sections of road, the eHighway truck has a hybrid drive. There are no restrictions on the type of hybrid drive: depending on the application and customer requirements, serial and parallel concepts with internal combustion engines, battery solutions, fuel cells etc. can all be implemented. The electric motors of the eHighway trucks also enable recovery of the vehicle’s braking energy.

Benefits and highlights:

- Innovative freight traffic solution

- Combines efficiency of electified railroads with flexibility of trucks

- Economical and environmentally friendly

- Applicable for various use cases: Shuttle transport, Electrified freight transport in mines, Electrified long-haul traffic

- Consists of three core elements: the energy supply, the pantograph, and hybrid drive technology

Source: Siemens, Scania Trucks & German Autobahn